BULK DISCOUNTS

A common twist to exam questions is to ask students to evaluate whether bulk discounts are worth taking. While prices reduce, total annual holding costs will increase if more stock is ordered at a time, so the matter needs a little thought.

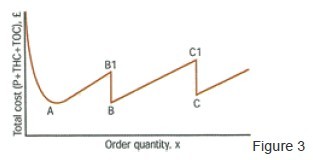

The common approach is one of trial and error. This involves finding the total annual cost (holding cost, re-ordering cost and purchasing cost) at the level indicated by the EOQ and at the level(s) where discount first becomes available. Figure 3 shows total costs (now including cost of purchasing the stock) plotted against order quantity with discount incorporated.

Point A represents the cost at the order quantity indicated by the EOQ. If stock is ordered in larger quantities, total costs will increase to point B1, at which stage bulk discounts are available, bringing the costs down to point B. Any calculations will involve finding which cost out of A, B or C is the lowest, as Example 1 will show.

Example 1

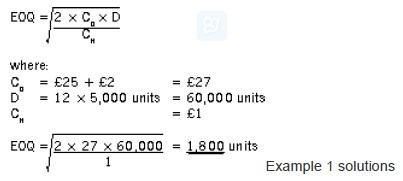

Moore Limited uses 5,000 units of its main raw material per month. The material costs £4 per unit to buy, supplier’s delivery costs are £25 per order and internal ordering costs are £2 per order. Total annual holding costs are £1 per unit. The supplier has offered a discount of 1% if 4,000 units of the material are bought at a time.

Required:

1. Establish the economic order quantity (EOQ) ignoring the discount opportunities.

2. Determine if the discount offer should be accepted.

RE-ORDER LEVELS

As important as how much to order at a time is the question of when to order more stock. If an order is placed too late, when stocks have been allowed to run too low, a ‘stock-out’ will occur, resulting in either a loss of production or loss of sales, or possibly both.

If orders are placed too soon, when there are still substantial supplies in stock, then stock levels and holding costs will be unnecessarily high. The re-order level as explained below should not be confused with the stock control levels referred to in textbooks – this article ignores these. When it comes to calculating re-order levels, three sets of circumstances can be envisaged.

LEAD-TIME IS ZERO

‘Lead-time’ is the interval between placing an order with a supplier and that order arriving. It is unlikely that this could be reduced to zero – it would require astonishingly co-operative and efficient suppliers. If it were possible, a re-order level of zero could be adopted. An organisation could simply wait until it ran out of stock, click its corporate fingers, and stock would arrive instantaneously.

CONSTANT DEMAND, FIXED FINITE LEAD-TIME

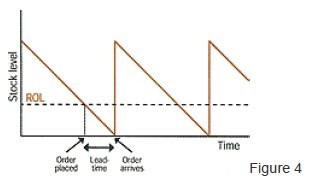

The assumption of constant demand is consistent with the assumptions underlying the EOQ formula. If suppliers take some time to provide goods, orders need to be placed in advance of running out. Figure 4 illustrates the problem and its solution.

If the lead-time is, say, 5 days, an order has to be placed before stocks have been exhausted. Specifically, the order should be placed when there is still sufficient stock to last 5 days, i.e:

Re-order level (ROL) = Demand in lead-time

So, if lead-time for a particular stock item is 5 days and daily demand is 30 units, the re-order level would be 5 days at 30 units per day, 150 units.

VARIABLE DEMAND IN THE LEAD-TIME

If demand in lead-time varied, it could be described by means of some form of probability distribution. Taking the previous example of the demand in lead-time being 150 units, we’re considering the possibility of demand being more than 150 or less than that. See Figure 5.

Note: This aspect of stock control produces a few problems. The EOQ formula requires that demand (and lead-time) for a stock item be constant. Here the possibility of demand varying or lead-time varying or both varying is introduced. Setting that problem aside, most ACCA syllabuses at the lower levels avoid any discussion of uncertainty or probability distributions. However, uncertainty in lead-time demand in stock control has featured in exams.

In these circumstances, a firm could place an order with a supplier when the stock fell to 150 units (the average demand in the lead-time). However, there’s a 33% chance (0.23 + 0.08 + 0.02 = 0.33) that demand would exceed this re-order level, and the organisation would be left with a problem. It is therefore advisable to increase the re-order level by an amount of ‘buffer stock’ (safety stock).

BUFFER STOCK

Buffer stock is simply the amount by which ROL exceeds average demand in lead-time. It is needed when there is uncertainty in lead-time demand to reduce the chance of running out of stock and reduce the cost of such shortages.

If a ROL of 160 units was adopted, this would correspond to a buffer stock of 10 units (and reduce the chance of running out of stock to 0.08 + 0.02 = 0.1, or 10%). A ROL of 170 is equivalent to a buffer stock of 20 and reduces the chance of running out to 2%, and a ROL of 180 implies 30 units of buffer stock (and no chance of running short).

OPTIMAL RE-ORDER LEVELS

This leaves the problem of how to calculate the optimal ROL. There are two common ways in which one could determine a suitable re-order level (if the information was available):

1. A tabular approach – Calculate, for each possible ROL (each level of buffer stock) the cost of holding different levels of buffer stock and the cost incurred if the buffer is inadequate (‘stock-out’ costs). The optimal re-order level is that level at which the total of holding and stock-out costs are a minimum.

2. A ‘service level’ approach – An organisation has to determine a suitable level of service (an acceptably small probability that it would run out of stock), and would need to know the nature of the probability distribution for lead-time demand. These two would be used to find a suitable ROL.

Tony Mock is a freelance lecturer and writer and an ACCA subject coordinator

Page 1 2 The original article>>

精品好课免费试听